Sustainability metrics

The production of denim has many steps and processes which can cause significant environmental impact due to the use of chemicals, water consumption and energy use. In order to assess this, it is important to look at data and find metrics that provide a standardized way to measure and monitor impact, allowing stakeholders to track progress, set goals and collaborate towards a more sustainable future for denim manufacturing.

One of the most commonplace metrics in the denim industry is an EIM score, short for Environmental Impact Measurement, created by Jeanologia. It has become a well-used standard for the fashion industry with more than 50 brands and 250 laundries using the tool within their garment finishing. The software tracks water consumption, energy consumption, chemical usage and worker health in the finishing process at laundries and then generates a score rated high to low impact.

The score breaks down the wash recipe which can be used to identify areas where improvements can be made. Therefore allowing stakeholders to optimize consumption and minimize negative environmental effects.

Recently, Jeanologia have announced an updated version 2 of the software, adjusting the way in which the EIM score is calculated. This change has been driven by the continuous advancements in sustainable practices, highlighting that what was once considered ‘good’ is now no longer valid. Some of the changes include making the use of chemicals more transparent, by scoring chemicals in conformance with ZDHC. Further to this it encourages automation rather than manual data input which helps with consistency of results between users.

It does however come with some disadvantages, with stricter calculations it is much harder than before to achieve a green EIM score. In addition, changing the standard makes it challenging for data comparison when reporting against scores calculated through version 1.

Although the changes have caused some controversy, it has allowed open discussion and collaboration between Jeanologia with other brands and laundries which inevitably is the key to the success of any push for sustainability. For Jeanologia, this was their way in continuing to strive for best in class results.

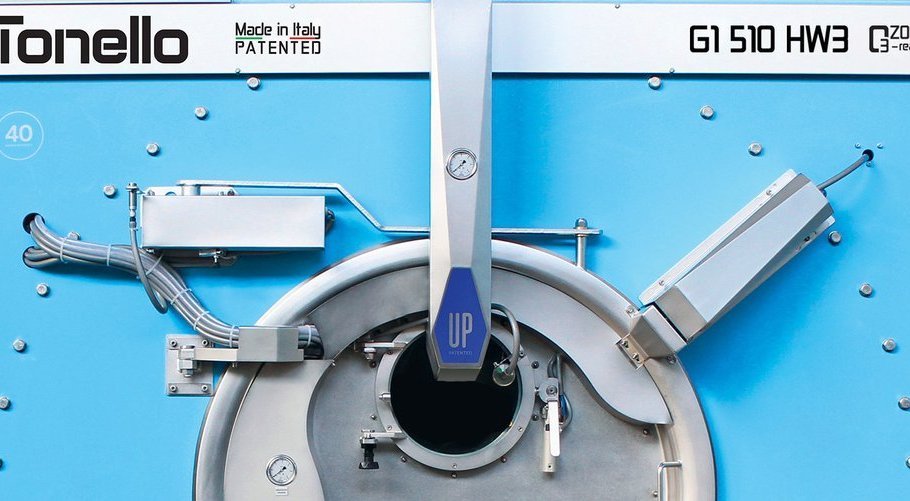

Another similar software building traction is part of Tenello’s Laundry (R)evolution, an all-in-one system used to control all laundry consumption, optimize process times and improve performance. Their software Metro captures real time data and enables centralised management and automatic analysis of all Tenello machines.

It is a digital platform that creates an ‘environmental passport’ based on real transparent and non-manipulable data. The report shows usage of energy, water and chemicals including a calculation for the carbon footprint relating to the washing or dyeing process.

The concept behind its application is to integrate its use in line with their all-in-one system. This performs all washing operations together by bringing together 4 integrated sustainable technologies in one machine: EGO, NoStone®, UP, and Core 2.0.

The disadvantage to this software is that it is specific to Tenello systems, meaning it is difficult to translate the program to laundries using other machinery. That being said, with open communication and collaboration, there is the potential to expand it’s usage. Tenello pride themselves on transparency and understand that to make the biggest impact sharing knowledge is key. This is in part why they have joined the Transformers Transparency Tool, a platform for providing a comprehensive and transparent view of a product's environmental impact.

Although the denim industry currently lacks a global standard which everyone is aligned to, systems such as EIM or Metro are a great starting point for tracking and impacting real change. Without this kind of reputable data it is not possible to effect change which is essential for ensuring a more responsible and ethical industry.